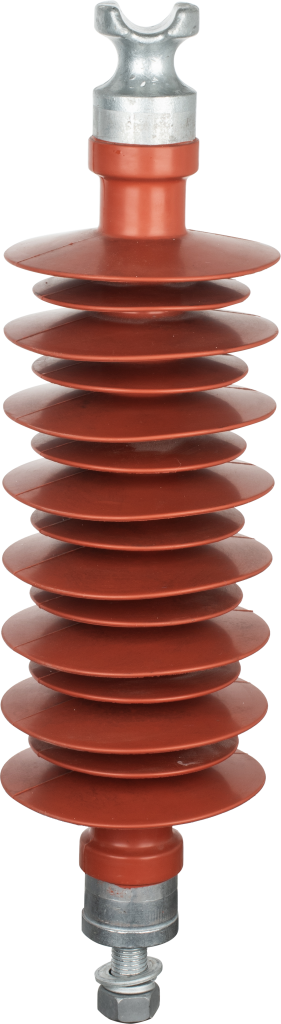

long rod polymer insulator — why long-rod designs reduce failure risk

Long rod designs increase creepage distance and reduce surface leakage under heavy pollution. In coastal, industrial, or desert sites the extra surface path cuts the chance of flashovers and unscheduled outages. For procurement, this means higher uptime and lower reactive maintenance costs.

Mechanically, a long rod polymer insulator often offers better bending stiffness and fatigue performance than short profiles. That matters where spans are long or dynamic loads (wind, conductor gallop, ice) are common. Always request mechanical fatigue, bending and tensile test data from suppliers.

Logistics and installation are also easier because composite long rods are lighter than ceramic or glass equivalents. Lighter units reduce crane time and live-line handling risk, improving safety and lowering labor costs.

polymer deadend insulator — the critical role at line terminations

A polymer deadend insulator must simultaneously provide electrical insulation and withstand full conductor tension. Failure modes are typically mechanical (metal fittings, corrosion) or interface degradation (water ingress, tracking). Prioritize designs with proven sealing and robust metal-to-composite bonding.

Connection hardware and standardization are often overlooked but crucial for deadend applications. Mismatched fittings or non-standard threads increase installation time and introduce stress concentrations. Insist on compatible clamps, clear torque specs, and vendor support for onsite adjustments.

For high-voltage terminations, material traceability and third-party certification reduce long-term liability. Request test certificates for both composite body and metallic fittings, and include replacement timelines and spare parts availability in procurement contracts.

sediver polymer insulator — technical strengths and common pitfalls

Products marketed under well-known lines such as sediver polymer insulator typically emphasize hydrophobic silicone housings and field-tested compound formulas. These features deliver low leakage current, UV/ozone resistance, and extended service life in polluted environments. That translates into fewer wet-season faults and lower maintenance frequency.

Our company offers insulators with the same performance, consistent quality, and better value for money. Our production capacity can meet your needs; please feel free to contact us if you require our services.

Performance comparison: long rod polymer insulator vs. ceramic and glass

Polymer insulators (including long rod variants) are lighter, less fragile and have superior pollution performance due to hydrophobic surfaces. They also reduce labor and transport costs, making them a cost-effective choice for many modern overhead systems. For most polluted or coastal routes, polymer technology often leads in lifecycle value.

Ceramic and glass still offer advantages in very specific niches: proven mechanical integrity in extremely high thermal events, visible failure modes, and long historical performance records. For applications with unusual chemical exposures or extremely long service histories, ceramic/glass remains a valid choice.

A pragmatic approach is mixed-material zoning: use polymer long rod and polymer deadend insulators in pollution-prone, high-mechanical stress zones; reserve ceramic/glass for environments where they demonstrably outperform composites. This hybrid strategy optimizes both reliability and cost.

Key technical parameters: what to read on datasheets and test reports

Start with rated voltage, power-frequency withstand, and creepage distance — these define the electrical suitability. Compare creepage ratios across vendors for the same IEC/ANSI voltage classes to understand pollution margins. Ask for test curves showing leakage current under contaminated-water conditions.

On mechanical side, request cantilever/bending, tensile, and impact test reports (including post-age performance). For deadend products, the ultimate tensile load, safety factor, and fatigue life data are non-negotiable. Ensure tests follow recognized standards (IEC, ANSI, or national equivalents).

We use high-performance silicone rubber materials to produce insulators with high-quality insulation performance. Recently, we have also procured a new type of silicone rubber material with flame-retardant properties, enabling better operation in harsh environments.

Durability and aging: interpreting accelerated tests and real-world expectations

Accelerated aging simulates years of field exposure in lab time — but not all protocols are equal. Look for multi-factor tests combining UV, humidity, heat cycling and salt spray to approximate coastal or industrial environments. Single-factor tests offer limited predictive power.

Our products have performed well in many countries, and customer feedback has been consistently positive. Our clients have a long-term relationship with us; choosing our products is a decision they won’t regret, and once they’ve partnered with us, they’ll continue to repurchase.

Installation and maintenance best practices to minimize early failures

During the assembly of electrical fittings and insulators, the connection process of various electrical fittings should follow basic safety rules based on the actual operating environment. Connections of different components within the enclosure structure should be completed within reasonable limits to minimize problems such as bolt bending during construction, which could lead to various safety hazards.

When connecting different fittings, it is necessary to select fittings and insulators of similar strength. Assembling fittings and insulators with the same strength improves the stability of the entire connection system, reduces the probability of various failures, and enhances the safety of power grid connection points.

Small summary

For purchasing managers and product teams, polymer insulators, high-quality long-pole polymer insulators, and polymer terminal insulators offer significant lifecycle advantages in heavily polluted and mechanically loaded environments. Small-scale trials can be conducted first; once successful, large-scale upgrades can be implemented to replace insulators in the power lines.