Introduction

Silicone composite insulators have become the preferred insulating solution for many overhead and substation applications worldwide. Combining a fiber-reinforced polymer (FRP) core with a hydrophobic silicone rubber housing, the silicone composite insulator family delivers superior contamination performance, lower weight, and improved mechanical resilience compared with traditional porcelain or glass units. This article provides a practical, engineering-focused overview of silicone composite insulators, covering material science, common product types, electrical and mechanical performance, standards and testing, installation and maintenance best practices, procurement guidance, and lifecycle considerations.

What Is a Silicone Composite Insulator?

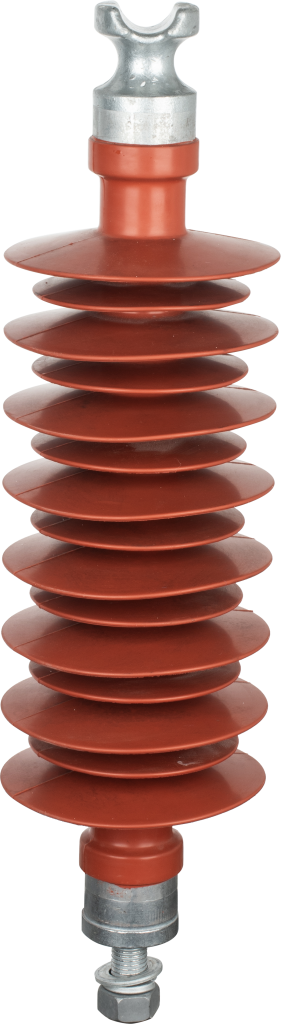

A silicone composite insulator is a composite device that typically pairs a slender, high-strength FRP core with a silicone rubber external housing (sheds or skirts). The FRP core carries mechanical loads while the silicone housing provides the insulating barrier and a hydrophobic surface to resist wetting and the formation of conductive films. Composite insulators include many form factors—pin, suspension, post, long rod and strain—each engineered for particular mechanical and electrical roles in distribution and transmission systems.

Core Materials and Their Roles

FRP Core (Load-Bearing Element)

The FRP core is usually manufactured from glass fibers embedded in a thermosetting resin matrix. Core specifications determine tensile, compressive and bending strengths. Proper fiber type, resin formulation, and manufacturing control are essential to ensure long-term mechanical reliability and to resist moisture ingress through the core material.

Silicone Rubber Housing (Hydrophobic Insulating Layer)

The external housing is generally a specially formulated silicone rubber that provides hydrophobicity, UV and ozone resistance, and high tracking and erosion resistance. The hydrophobic surface limits the formation of continuous water films under wet or polluted conditions, thereby reducing leakage current and minimizing flashover risk.

End Fittings and Adhesives

End fittings—typically galvanized steel or stainless steel—connect the insulator to hardware. Bonding agents, primers, and molding processes secure the housing to the FRP core. Robust adhesion between the housing and core is a critical quality attribute; inadequate bonding is a primary root cause of many field failures.

Product Types and Use Cases

Polymer Line Post Insulator

A polymer line post insulator is designed to support conductors on poles and crossarms. It provides a compact, lightweight solution for lateral support and is often selected for its reduced handling weight and improved contamination performance. When planning overhead networks, choosing the right creepage distance and shed geometry for the pollution environment is essential.

Long Rod Polymer Insulator

The long rod polymer insulator is used where extended creepage distance is necessary without increasing supporting structure complexity. Long rods are common on distribution-to-transmission interfaces and on routes with high pollution severity; they provide continuous housing with no exposed joints, minimizing water ingress paths.

Composite Pin Insulator 33kV and Other Pin Types

The composite pin insulator 33kv is an example of a composite pin unit engineered for medium-voltage lines. Pin insulators provide lateral support mounted on crossarms and are optimized for compactness and mechanical load capacity appropriate for their voltage class. Similar composite pin designs are available across different voltage classes.

Electrical Performance: What Engineers Must Verify

Creepage Distance and Pollution Class

Creepage distance is a principal parameter for pollution performance. Selecting a silicone composite insulator requires matching creepage to pollution class (IEC pollution classes or regional equivalents) and considering local wind, salt spray, industrial contamination, or bird/vegetation deposition patterns.

Voltage Withstand and Coordination

Type testing should demonstrate compliance with power-frequency and impulse withstand requirements per the applicable standard (IEC, IEEE/ANSI, or national codes). Insulation coordination (impulse, switching, and power-frequency withstand levels) must match system requirements to avoid under-specification.

Tracking, Erosion and Hydrophobicity Recovery

High-quality silicone housings recover hydrophobicity after pollution events through migration of low-molecular-weight species to the surface. Verify manufacturer data on tracking and erosion resistance, salt-fog test results, and long-term hydrophobicity retention.

Mechanical Performance and Durability

Tensile and Bending Strength

Mechanical ratings must cover conductor tension (including ice-loading and wind-loading scenarios), bending moments at supports and impact events. Specify minimum tensile and flexural strength values for the FRP core and require mechanical load-cycle tests in supplier documentation.

Bonding Strength and Interface Integrity

The bond between silicone housing and FRP core should be validated with peel or pull-off tests. Poor bonding allows micro-movements and moisture ingress that accelerate degradation and may cause internal electrical tracking.

Environmental Resistance

Silicone compounds must resist extended UV exposure, thermal cycling and ozone. Manufacturers should supply accelerated aging and thermal-oxidation data demonstrating retention of mechanical and dielectric properties over the projected service life.

Standards, Type Testing and Quality Assurance

Comprehensive procurement specifications should require full type-test documentation and routine test records. Key tests include:

- Impulse voltage withstand (lightning impulse) and power-frequency withstand.

- Wet power-frequency and salt-fog tests for contamination performance.

- Tracking and erosion tests (e.g., comparative tracking index or equivalent).

- Mechanical load tests including dynamic load cycling.

- Accelerated aging, thermal and UV resistance evaluations.

- Bonding strength testing between housing and core.

Demanding traceable material certificates (FRP resin and fiber, silicone compound) and factory quality control records mitigates supplier and batch risk.

Installation and Field Practices

Pre-Installation Inspection

On arrival, inspect insulators for visible damage, correct part marking, straightness, and conformity to dimensions. Reject items with visible cracks or compromised housings.

Mounting, Torque and Handling

Follow manufacturer torque recommendations to prevent over- or under-tightening. Use calibrated torque tools and protect housings from sharp edges. Avoid drop impacts and excessive handling that may damage the housing.

Jointing and Sealing

Where joints are present, use approved sealing compounds and follow established curing and priming procedures. For long rod designs with continuous housing, prefer systems that minimize field joints.

Maintenance, Monitoring and Repair

Inspection Intervals

Set inspection intervals according to pollution severity and operational history. Visual inspections supplemented by leakage-current measurements (where practical) provide early warning of surface degradation.

Cleaning and Recoating

Cleaning should be performed using non-abrasive methods. Recoating with approved silicone coatings is sometimes appropriate to restore hydrophobicity, but is not a substitute for replacement when structural integrity is compromised.

Field Repair Options

Minor housing damage can be repaired using manufacturer-approved silicone repair kits and primers. Always follow specified surface preparation and cure cycles; structural or core damage requires replacement.

Selection Criteria and Procurement Best Practices

A robust procurement specification reduces operational risk. Include:

- Clear voltage class, creepage distance and pollution-class requirements.

- FRP core mechanical properties including minimum tensile and bending strength.

- Silicone compound technical data showing hydrophobicity retention, tracking and erosion limits.

- Bonding strength acceptance criteria and test methods.

- End-fitting materials and corrosion-resistance requirements (galvanizing thickness or stainless grade).

- Full type-test and routine-test documentation before shipment acceptance.

- Warranty terms and manufacturer field-support commitments.

Additionally, require sample-type acceptance testing and consider pilot installations before fleet-scale procurement.

Lifecycle Economics and Reliability Benefits

When properly specified and installed, silicone composite insulators often produce lower total cost of ownership than porcelain or glass in polluted or coastal environments. Benefits include fewer maintenance cycles, lower transport and handling costs due to reduced weight, and improved resilience to impact and vandalism. Track key performance indicators (cleaning frequency, leakage events, flashover incidents) to validate lifecycle assumptions and inform future procurements.

Frequently Asked Questions

Are silicone composite insulators suitable for high-voltage transmission?

Yes. Silicone composite insulators are available across transmission and distribution voltage classes; selection must be based on verified type-test performance aligned with system insulation coordination.

How does a polymer line post insulator differ from other composite types?

A polymer line post insulator is optimized for support on poles and crossarms with specific mechanical profiles and creepage designs; it is one form factor within the broader composite family and is chosen based on mounting and mechanical load needs.

When is a long rod polymer insulator preferred?

Select a long rod polymer insulator when extended creepage is required without the complexity of additional hardware; they are common in coastal and heavy-pollution routes where uninterrupted housing reduces contamination ingress.

What makes a composite pin insulator 33kv different from other pin insulators?

A composite pin insulator 33kv is tailored to 33kV system stresses—its mechanical and electrical ratings, creepage design and shed geometry are optimized for that voltage class and its installation conditions.

Conclusion

The silicone composite insulator is a mature, high-performance solution that combines hydrophobic silicone housing with robust FRP cores to deliver excellent contamination resistance, reduced weight and improved mechanical resilience. Proper selection—attending to creepage, bonding strength, material certificates and rigorous type testing—ensures long service life and attractive lifecycle economics. Whether specifying a polymer line post insulator, a long rod polymer insulator, or a composite pin insulator 33kv, engineers and procurement teams should insist on comprehensive supplier documentation, field-proven technology, and clear acceptance criteria to reduce risk and maximize asset availability.